Meet Bruno

MEET BRUNO

Bruno is a self-driven, reliable, constructive, knowledgeable and dedicated specialized engineer.

An independent adsorption specialist who focuses on improving reliability of adsorption units.

Bruno is the go-to person for industrial adsorption issues.

Bruno with his wife, Ingrid

Bruno is a self driven, reliable, constructive, knowledgeable and dedicated specialised engineer.

Bruno is an independant adsorption specialist focussing on improving reliability of adsorption units.

Bruno is the go-to person for industrial adsorption issues

Our Offering

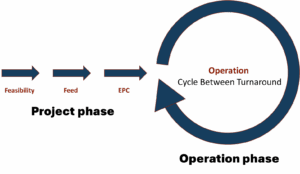

Asset Lifecycle

From early project phase to daily operation, we help you get reliable performance out of adsorption systems.

In order for your adsorption unit to perform as predicted, all aspects of the unit must be correct. This requires a proactive approach in the different phase of the project and during the life of the unit.

Feasibility study

during the feasibility study process unit are connected to oneanother. Having acess to an adsorption expert allows you to quickly iterate to the most optimal solutions for your future plant. This avoids costly rework afterwards.

FEED Study

During the feed, PFDs (Process Flow Diagrams) are reviewed and designs are adjusted one last time. To avoid issues in the future we also review the plot plan. By getting involved here, we ensure the fundamental design is sound, preventing costly changes later in the project.

EPC phase

During the EPC phase, we will audit documentation (PFDs, P&IDs,MEchnaical drawings, procedures) to de-risk the start-up and operation of the plant. We provide SME support for HAZOP reviews, audit vendor procedures, and physically witness the adsorbent loading. We also build your dashboards in prepareation for the start up.

Operation Phase

After the start up and the performance test run, we provide Reactive Support for the unexpected. Whether it is a pressure drop spike or an impurity breakthrough, we perform Root Cause Analysis to solve the problem and restore stability.

Cycle Between Turnaround

Our ultimate goal is to provide reliability. We support the operator by providing guidance to perform breakthrough test where meaning full.

By catching risks in the EPC phase and troubleshooting quickly during operation, we ensure the unit runs uninterrupted until its scheduled maintenance window.

Help in every stage

From early project phase to daily operation, Bruno helps you get reliable performance out of adsorption systems.

In order for your adsorption unit to perform as predicted, all aspects of the unit must be correct. I deliver fact-based CAPEX and OPEX estimates, train operators and engineers to truly understand their process, and resolve breakthrough, pressure drop, or capacity loss by fixing root causes not symptoms so your unit runs safer, longer, and as designed.

Cost Estimates

Planning a new adsorption unit or major revamp?

First we listen to your needs so that we can taylor a solutions to your needs deliver realistic cost estimates covering both CAPEX and OPEX including adsorbent lifetimes and energy use so your investment decisions are driven by facts, ROI, and zero surprises.

Adsorption Training

Maximize your installation’s value with targeted training for operators and process engineers from adsorption fundamentals to advanced process control so your team understands not just how the system runs, but why, delivering safer operation and longer bed life.

Trouble Shooting

Seeing early breakthrough, rising pressure drop, or lost capacity? I cut through the noise, analyze your process data, and fix the real root cause whether that means correcting regeneration strategy or eliminating mechanical faults to restore performance fast.

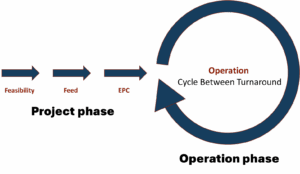

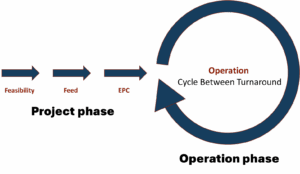

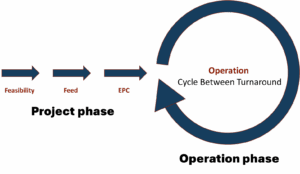

Asset Lifecycle

From early project phase to daily operation, we help you get reliable performance out of adsorption systems.

In order for your adsorption unit to perform as predicted, all aspects of the unit must be correct. This requires a proactive approach in the different phase of the project and during the life of the unit.

Feasibility study

during the feasibility study process unit are connected to oneanother. Having acess to an adsorption expert allows you to quickly iterate to the most optimal solutions for your future plant. This avoids costly rework afterwards.

FEED Study

During the feed, PFDs (Process Flow Diagrams) are reviewed and designs are adjusted one last time. To avoid issues in the future we also review the plot plan. By getting involved here, we ensure the fundamental design is sound, preventing costly changes later in the project.

EPC phase

During the EPC phase, we will audit documentation (PFDs, P&IDs,MEchnaical drawings, procedures) to de-risk the start-up and operation of the plant. We provide SME support for HAZOP reviews, audit vendor procedures, and physically witness the adsorbent loading. We also build your dashboards in prepareation for the start up.

Operation Phase

After the start up and the performance test run, we provide Reactive Support for the unexpected. Whether it is a pressure drop spike or an impurity breakthrough, we perform Root Cause Analysis to solve the problem and restore stability.

Cycle Between Turnaround

Our ultimate goal is to provide reliability. We support the operator by providing guidance to perform breakthrough test where meaning full.

By catching risks in the EPC phase and troubleshooting quickly during operation, we ensure the unit runs uninterrupted until its scheduled maintenance window.

Help in every stage

From early project phase to daily operation, Bruno helps you get reliable performance out of adsorption systems.

In order for your adsorption unit to perform as predicted, all aspects of the unit must be correct. I deliver fact-based CAPEX and OPEX estimates, train operators and engineers to truly understand their process, and resolve breakthrough, pressure drop, or capacity loss by fixing root causes not symptoms so your unit runs safer, longer, and as designed.

Cost Estimates

Planning a new adsorption unit or major revamp?

First we listen to your needs so that we can taylor a solutions to your needs deliver realistic cost estimates covering both CAPEX and OPEX including adsorbent lifetimes and energy use so your investment decisions are driven by facts, ROI, and zero surprises.

Adsorption Training

Maximize your installation’s value with targeted training for operators and process engineers from adsorption fundamentals to advanced process control so your team understands not just how the system runs, but why, delivering safer operation and longer bed life.

Trouble Shooting

Seeing early breakthrough, rising pressure drop, or lost capacity? I cut through the noise, analyze your process data, and fix the real root cause whether that means correcting regeneration strategy or eliminating mechanical faults to restore performance fast.